AquaIMPACT researchers are working on methods to select fish automatically, quickly and accurately. The shape and colour characteristics of farmed fish must be assessed. This allows the breeder to decide which fish will be used for further breeding. This time consuming measurement is now done by hand.

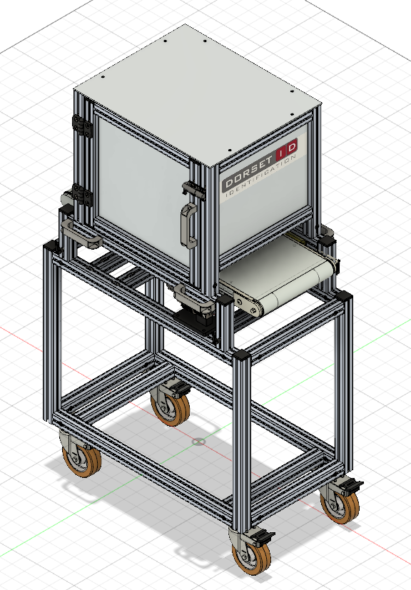

The use of machine vision techniques has many advantages. With vision techniques a higher number of samples and more variables can be measured in a shorter time. In addition, software is more objective and has a higher repeatability than a human observer. WUR is developing the device together with the company DORSET for measuring the various variables (such as the 2D and 3D shape, colour and properties of body parts such as eyes or belly). The fish are thereby manually removed from the breeding tank and placed on a conveyor belt. An algorithm merges the colour and shape characteristics of the fish with genetic information from a database.

The use of machine vision techniques has many advantages. With vision techniques a higher number of samples and more variables can be measured in a shorter time. In addition, software is more objective and has a higher repeatability than a human observer. WUR is developing the device together with the company DORSET for measuring the various variables (such as the 2D and 3D shape, colour and properties of body parts such as eyes or belly). The fish are thereby manually removed from the breeding tank and placed on a conveyor belt. An algorithm merges the colour and shape characteristics of the fish with genetic information from a database.

After analysis a selection algorithm will classify the individual fish in real-time to be selected or not to be selected for further breeding. The device then mechanically sorts the fish two groups. For one fish, the entire operation is completed in approximately 30 seconds. As a result, the fish has as little stress as possible. Smart phenotypes using artificial intelligence and integrating phenotyping and selection decisions in one step reduces the handling (stress) of fish and increases the speed and efficiency of breeding programmes.

The AquaIMPACT device will have the following characteristics:

- Mobility for the easy transport.

- Can be operated in outdoors in variable daylight conditions.

- Can automatically read RFID tag of individuals, measure weight.

- Real-time classification and sorting.

- Measures calibrated color 2D features and can extracts landmarks

- 3D image analysis for volume reconstruction.

The phenotyping prototype to be developed in AquaIMPACT shows a powerful way of implementing big data with novel algorithms for processing and reasoning into a practical application and product.

Wageningen University & Research is specialised in sensing and phenotyping of both plants and animals with non-destructive, fast and robust applications. In co-development with machine builders and breeding companies we develop objective methods to collect data for describing variety performances in all stages of (re)production.

Machine vision based sorting systems for seedlings, pot-plants and cut-flowers are used by all major commercial growers and breeders. For this task products get usually transported one-by-one on a conveyor belt or similar through a measurement cabinet with an installed artificial light and one or several cameras. These systems can measure physical plant dimensions such as e.g. length and width, number and/or size and/or shape of flowers and shoots and/or derived features from such measurements. While 2D color image analysis is already very common, there is a clear trend towards more sophisticated 3D image analysis.

Text: Jochen Hemming (WUR), Roland Stump (Dorset ID)